- 1 Introduction

- 2 The Black Country 2039: Spatial Vision, Strategic Objectives and Strategic Priorities

- 3 Spatial Strategy

- 4 Infrastructure & Delivery

- 5 Health and Wellbeing

- 6 Housing

- 7 The Black Country Economy

- 8 The Black Country Centres

- 9 Transport

- 10 Environmental Transformation and Climate Change

- 11 Waste

- 12 Minerals

- 1 Sub-Areas and Site Allocations

- 2 Delivery, Monitoring, and Implementation

- 3 Appendix – changes to Local Plans

- 4 Appendix – Centres

- 5 Appendix – Black Country Plan Housing Trajectory

- 6 Appendix – Nature Recovery Network

- 7 Appendix – Glossary (to follow)

Draft Black Country Plan

(5) 12 Minerals

Introduction

12.1 Strategic plans are expected to make sufficient provision for all kinds of development, including for minerals (NPPG paragraph 20b). The policies for minerals in this Chapter also support the overall Vision, Objectives and Strategic Priorities, notably Strategic Objective Meeting our resources and infrastructure needs and Strategic Priority 14 for the plan, by ensuring that in 2039, the Black Country will:

a) use its remaining mineral resources responsibly, including maximising the use of alternatives to produce a steady and adequate supply of minerals and mineral products to support the local economy and growth;

b) ensure that other development does not needlessly prevent mineral resources from being worked in the future if it is feasible and economically viable to do so; and

c) manage and produce mineral products in ways that avoids significantly harming the environment and the health and wellbeing of local communities.

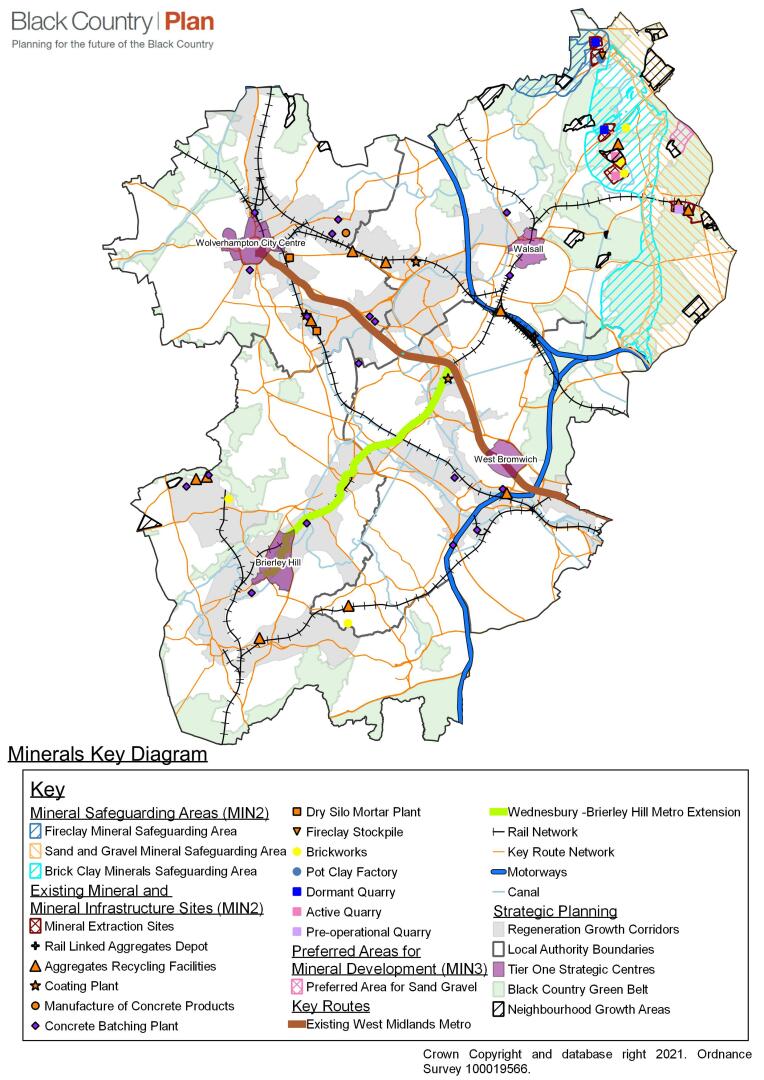

Figure 14 - Minerals Key Diagram

Mineral Production – Requirements

12.2 This policy identifies the requirements for production of aggregate minerals and industrial minerals in the Black Country over the plan period, having regard to national policy guidance on provision for these minerals, the likely demand for them over the plan period, the constraints to working them in the Black Country, and the contribution likely to be met through imports of these minerals from other areas.

(5) Policy MIN1 - Mineral Production – Requirements

- To enable the Black Country to make an appropriate contribution towards identified local and regional requirements, the following provision is identified for minerals over the plan period.

Construction Aggregates

Primary Land Won Sand and Gravel

- Sufficient provision has been identified in this plan to enable the Black Country to supply at least 25% of the seven-year sand and gravel landbank for the West Midlands Metropolitan Area (WMMA)[95] over the plan period. This equated to 6.2 million tonnes in total at the end of 2017, sufficient to provide for an average annual production rate of 120,000 tonnes per annum[96]. The other resources in the Minerals Safeguarding Areas (MSAs) also have the potential to contribute towards future sand and gravel production.

Secondary and Recycled Aggregates

- At the end of 2017, the Black Country was estimated to be producing around 720,800 tonnes of secondary and recycled aggregates per annum at permitted production sites[97]. As a minimum, the Black Country will aim to maintain this level of production throughout the plan period. In support of this, permitted secondary and recycled aggregate sites expected to continue in production up to 2039 will be safeguarded (see Policy MIN2).

Efficient Use of Mineral Resources

- All new developments will be encouraged to be resource-efficient, by making the maximum possible use of recycled mineral products in construction, to reduce reliance on quarried products and help maintain existing supplies for longer.

Industrial Minerals

Brick Clay (Etruria Marl)

- Sufficient brick clay provision has been identified in this plan to meet the supply requirements of the operational brick manufacturing plants in the Black Country over the plan period, allowing for continued imports from other areas. At the end of 2017 there were around 10 million tonnes of permitted reserves of Etruria Marl in Walsall. Subject to availability and assuming continued importation of material this would be sufficient to provide a 25-year supply to Aldridge, Atlas and Sandown brickworks in Walsall, based on the expected future annual consumption rates of these factories. This brick clay resource should therefore be safeguarded from inappropriate development (see also Policy MIN2).

Fireclay

- Sufficient fireclay provision has been identified in this plan to meet the supply requirements of Swan Works in Walsall over the plan period. The existing stockpile and permitted reserves identified in Policy MIN3 and the other potential resources within the MSA have the capability to provide a 25-year supply of fireclay to this factory. They could also provide a long-term supply to brick manufacturing plants in Walsall, assuming that the fireclay present meets the requirements of the operators. This Fireclay resource should therefore be safeguarded (see also Policy MIN2).

Justification

12.3 Planning policies for minerals should provide for the extraction of minerals of "local and national importance" (NPPF paragraph 204), including sand and gravel, brick clay and fireclay, which occur naturally in the Black Country.

12.4 Mineral Planning Authorities[98] are expected to maintain a landbank of at least seven years of permitted reserves of sand and gravel (NPPF paragraph 207) to ensure a steady and adequate supply of aggregates for the construction industry. This means that sites with planning permission for sand and gravel extraction need to have enough minerals left in them to sustain the expected demand over the whole of the plan period plus seven years beyond that. If the permitted reserves are not sufficient to meet this requirement, planning policies are expected to identify other sand and gravel resources that could be worked to make up the shortfall.

12.5 For brick clay, Mineral Planning Authorities are expected to maintain a stock of permitted reserves sufficient to meet the needs of each brick manufacturing plant over the next 25 years (NPPF paragraph 208). It is assumed (though it is not explicit) that the same requirement also applies to fireclay, which is used by brick manufacturers for blending with brick clay for the production of buff-coloured facing bricks and pavers. It is also used locally to manufacture pot clay blends at Swan Works in Brownhills, Walsall.

Construction Aggregates

Expected Demand over the Plan Period

12.6 Current national policy guidance on minerals identifies past sales as an indicator of current demand for aggregate minerals (NPPF paragraph 207), but as it is not necessarily a reliable indicator of future demand, "other relevant local information" should also be taken into account when planning for future supplies. This evidence has been reviewed as part of the 2020 Black Country Minerals Study and is summarised below.

12.7 The economic recession has clearly had a significant effect on sales of sand and gravel in the West Midlands Metropolitan Area (WMMA) and wider West Midlands Region over the ten years up to 2017, which was the latest information available at the time the 2020 Black Country Minerals Study was prepared. Table 11 shows that there was a steep fall in sales in 2009 in the WMMA, followed by a gradual increase up to 2016, with sales falling back again in 2017.

Table 11 - Ten -Year Rolling Average Annual Sand and Gravel Sales in the West Midlands Metropolitan Area (WMMA) 2008-2017 (million tonnes)

|

Year |

2008 |

2009 |

2010 |

2011 |

2012 |

2013 |

2014 |

2015 |

2016 |

2017 |

|

Annual Sales |

0.500 |

0.375 |

0.451 |

0.401 |

0.461 |

0.491 |

0.498 |

0.529 |

0.577 |

0.480 |

|

Rolling ten-year average sales |

0.526 |

0.516 |

0.513 |

0.500 |

0.495 |

0.494 |

0.492 |

0.487 |

0.489 |

0.476 |

Source: Table 5.3 2020 Black Country Minerals Study; West Midlands Aggregates Working Party Annual Monitoring (AM) Reports 1999 - 2017

12.8 Based on the last ten-year average sales figure, the WMMA would need to identify nearly 13 million tonnes of permitted sand and gravel reserves and other potential sand and gravel resources to provide a 'rolling' landbank over the Black Country Plan period. Table 12 below shows how this has been calculated.

Table 12 - Sand and Gravel - West Midlands Metropolitan Area (WMMA) Landbank Requirement (million tonnes), December 2017

|

Sand and Gravel Landbank Requirement in West Midlands |

Million tonnes |

|

Ten-year average sales 2008 – 2017 |

0.48 |

|

20-year requirement to the end of the BCP Period in 2039[99] (ten-year average sales x 20 Years) |

9.60 |

|

Requirement for Landbank (ten-year average sales x seven years) |

3.36 |

|

Total Landbank Requirement (20 years + 7 Years) |

12.96 |

Source: Table 5.3 2020 Black Country Minerals Study

12.9 However, as Table 11 shows, the past ten years' average sales have been lower than sales prior to 2009 and are therefore not a reliable indicator of likely future demand in the Black Country, where significant housing and employment growth is planned over the plan period.

12.10 Another indicator of current demand for construction aggregates in the WMMA is provided by the national aggregate minerals surveys, which record consumption of construction aggregates by region and sub-region. The last survey to have been carried out in 2014 found that the WMMA consumed around 1.9 million tonnes of sand and gravel and around 1 million tonnes of crushed rock in that year. By comparison, consumption of sand and gravel in 2009 was estimated to have been around 1.6 million tonnes, and consumption of crushed rock around 1.3 million tonnes[100].

12.11 Reliable consumption figures for the pre-recession period are not available for the WMMA. However, data from the 2005 national survey indicates that Birmingham and the Black Country alone consumed at least 1 million tonnes of sand and gravel and at least 1.7 million tonnes of crushed rock[101].

12.12 The planned housing and employment growth in the Black Country over the plan period will increase the demand for minerals and will impact on mineral consumption. However, as established in the 2020 Black Country Minerals Study, it is difficult to quantify what the projected housing and employment growth mean in terms of the amount of minerals that needs to be planned for, specifically construction aggregates. The minerals provision in this plan will therefore be continually monitored in conjunction with continued liaison with those Minerals Planning Authorities who form the wider West Midlands region.

12.13 Notwithstanding the above, the requirement to maintain a 'rolling' landbank over the Black Country Plan period of nearly 13 million tonnes for sand and gravel (as set out in Table 12) remains unaffected.

Sand and Gravel Supply

12.14 Walsall is the only authority in the Black Country with sand and gravel resources that have the capability to be worked over the plan period. The main resource area is in the eastern part of Walsall Borough, in Aldridge and Stonnall.

12.15 Historically, Walsall has contributed up to 10% of the WMMA's annual sand and gravel production[102], although production in Walsall reduced significantly following the closure of the former Aldridge Quarry in 2008 and ceased completely when Branton Hill Quarry closed in 2013. This means that the majority of the WMMA's sand and gravel production is currently (2019) in Solihull, the only other authority in the sub-region with workable sand and gravel resources.

12.16 At the end of 2017, Solihull had nearly 4 million tonnes of permitted sand and gravel reserves. However, a high proportion of these reserves are expected to be sterilised by HS2 if it goes ahead, and this has already led to the closure of one site (Stonebrook Quarry). It is therefore unlikely that Solihull will be able to sustain the same rates of sand and gravel sales seen over the last ten years, at least in the short-term until new sites come forward.

12.17 The Draft Solihull Local Plan (2016) identified Preferred Areas and Areas of Search for sand and gravel, including in areas not affected by HS2. The Draft Plan estimates that there are around 2.5 million tonnes of sand and gravel resources within the Preferred Areas at Marsh House Farm, Hornbook Farm and west of Berkswell Quarry, but the full extent of the resource within the wider Areas of Search has not been quantified[103]. There is no guarantee that any of these reserves will come forward to replace those lost as a result of HS2.

12.18 If the landbank requirement is to be met, it is for the Black Country Plan to provide for as much sand and gravel production as possible to help reduce the shortfall created by the expected fall in production in Solihull.

12.19 At the end of 2018, the only permitted sand and gravel extraction site in Walsall was the Branton Hill Quarry Extension site, which received planning permission in August 2018 (application reference BC64995P). This site is identified in Policy MIN3 and on the Minerals Key Diagram (ref MX1). The site is estimated to have just over 1 million tonnes of permitted reserves of sand. The existing mineral permission has an end date of 31 December 2027, meaning that the site has the capability to produce up to 120,000 tonnes per annum over its eight-year life.

12.20 A Preferred Area for sand and gravel extraction has also been identified at Birch Lane around the former Aldridge Quarry, which remains unrestored. This area corresponds to the Area of Search identified in the Walsall Site Allocation Document (SAD) 2019 and is designated on the Policies Map for Walsall and is estimated to have around 5.2 million tonnes of unpermitted sand and gravel resources. If proposals come forward for sand and gravel working in this area it would enable production to continue beyond the current end date for the Branton Hill site.

12.21 The plan has therefore identified provision for up to 6.2 million tonnes of sand and gravel in total. This would in theory provide around half of the WMMA's current landbank requirement identified in Table 12 above. However, as there is only one permitted site and no guarantee that others will come forward, it is unlikely that all of these resources are capable of being worked during the plan period. A more realistic assumption would be that the anticipated production rate of 120,000 tonnes per annum at Branton Hill might be sustained to the end of the plan period if a new site comes forward within the Preferred Area at Birch Lane or elsewhere within the MSA. This would be equivalent to around 25% of the current WMMA supply requirement.

Crushed Rock Supply

12.22 The last quarry in the Black Country to produce crushed rock (dolerite), Edwin Richards in Sandwell, closed in 2008. As detailed in the 2020 Black Country Minerals Study, there are no winnable crushed rock resources remaining anywhere in the Black Country, therefore no provision is identified for this mineral.

12.23 Coating plants and construction projects in the Black Country are expected to continue to rely on imports of crushed rock from outside the area. The latest information available suggests that most of the crushed rock imported into the West Midlands Metropolitan Area is imported from Leicestershire, Shropshire, and Derbyshire.

Supply of Secondary and Recycled Aggregates

12.24 Secondary and recycled aggregate sites expected to continue in production up to the end of the plan period will be safeguarded (see Policy MIN2). Due regard should also be had to the relevant Black Country Plan waste policies (notably Policies W1 and W2).

Evidence

- Walsall SAD & AAP Minerals Study (2015), Amec Foster Wheeler

- Walsall Site Allocation Document: (2019), Walsall Council

- Black Country Minerals Study: Review of the Evidence Base for Minerals to support the preparation of the Black Country Plan (2020), Wood

Delivery

- Development Management – evaluation of minerals applications as they come forward.

- Duty to Co-operate – continued liaison with WMMA authorities as part of duty to cooperate obligations and liaison with the wider Minerals Planning Authorities in the West Midlands region.

Issues and Options consultation responses

12.25 Policy MIN1 will replace the relevant sections of existing BCCS Policies MIN2, MIN3 and MIN4. The policy seeks to bring together the mineral production requirements for all minerals in the Black Country under a single policy – construction aggregates (i.e. sand and gravel, secondary and recycled aggregates) and industrial minerals (i.e. brick clay and fireclay).

12.26 The mineral production requirements for each of the Black Country's minerals in the policy are set out in the supporting Black Country Minerals Study.

Minerals Safeguarding

12.27 This policy sets out how the most important mineral resources in the Black Country, and sites that are expected to be producing, processing or transporting minerals and mineral products, will be protected from other types of development that could compromise their continued operation over the plan period.

(10) Policy MIN2 - Minerals Safeguarding

Minerals Safeguarding Areas (MSAs)

- Minerals safeguarding areas (MSAs) have been defined around the following mineral resources in Walsall Borough:

- sand and gravel - Bedrock (Triassic, Sherwood Sandstone);

- brick clay - Etruria Formation (principal brick clay resource within Carboniferous Upper Coal Measures); and

- fireclay (potentially winnable resources underlying the principal coal seams within the Carboniferous - Upper Coal Measures).

- The MSAs are identified on the Minerals Key Diagram and on the Policies Map and are listed in each of the BCA sections in Chapter 13.

- Planning applications for non-mineral development will only be supported in an MSA where the development will not compromise existing or future mineral working within the MSA, and the following conditions are met:

- the development will involve the extraction of some or all of the mineral resource prior to development, where is practicable to do so; or

- it can be demonstrated that the site does not contain any mineral resources of economic value; or

- it can be demonstrated that the ‘prior extraction’ of minerals is not feasible.

- Applications for non-mineral development in an MSA should include supporting evidence demonstrating that one of the above criteria applies. Exceptions to this policy will apply to householder developments, conversions, and changes of use of existing buildings, and other forms of development that do not involve any new building or excavation works likely to sterilise mineral resources.

Non-minerals developments outside the MSAs

- Outside MSAs, mineral deposits that are identified as being, or may become of, economic importance will be safeguarded from unnecessary sterilisation.

- Where development is proposed, encouragement will be given to the extraction of the mineral resource prior to or in conjunction with, development, where this would not have unacceptable impacts on neighbouring uses. Developments over five hectares should be accompanied by supporting information (as set out in the Justification) demonstrating that mineral resources will not be needlessly sterilised.

Existing Minerals Sites

- The location of all permitted mineral extraction and mineral infrastructure sites are identified on the Minerals Key Diagram, and these sites are also listed in each of the BCA sections in Chapter 13. Applications for development within a 150m buffer zone of these sites will need to demonstrate they will not have any unacceptable impacts on these sites that would prevent them from continuing to operate.

(1) Justification

Minerals Safeguarding Areas (MSAs)

12.28 The Black Country is geologically very diverse. A wide range of mineral resources occur within the Plan area, including sand and gravel, brick clay, coal, fireclay, limestone and hard rock (dolerite), which are identified in national policy guidance as minerals of 'local and national importance (NPPF Annex 2 Glossary).

12.29 The exploitation of these resources in the past has had a significant impact on the history and development of the area. For example, the canal network was developed during the C18th and early C19th to improve the transportation of raw materials such as coal and limestone to important industrial centres. Historic coal, limestone and sand and gravel working has also left a legacy of sites of importance for geological conservation and biodiversity, as well as sites affected by ground instability.

12.30 Most of the Black Country's mineral resources are now either exhausted or sterilised by other development and are therefore not capable of being worked on a commercial scale. However, mineral working is still feasible in the eastern parts of Walsall where large-scale urban development has not yet taken place. The BCP seeks to safeguard those mineral resources in the Walsall area where there is a realistic potential for mineral extraction to take place over the plan period through the identification of MSAs for sand and gravel, brick clay (Etruria Marl), and fireclay. These MSAs have been identified following the review and refinement of the British Geological Society (BGS) mineral resource safeguarding maps and on information from the minerals industry (where this was provided). The adopted Walsall Site Allocations Document (2019) provides full details of the methodology employed to arrive at the MSAs.

Non-Minerals Developments outside the MSAs

12.31 To prevent the unnecessary sterilisation of minerals resources outside the identified MSAs, the prior extraction of these resources is encouraged where non-mineral development is proposed (except for conversions /changes of use that do not involve any new building or excavation works).

12.32 Mineral sterilisation issues will only generally come into play when larger development sites are concerned, i.e. those generally above five hectares, and such developments should be accompanied by supporting information demonstrating that mineral resources will not be needlessly sterilised. The supporting information should include details of a prior extraction scheme or, where this is not considered feasible, evidence that:

a) mineral resources are either not present, are of no economic value or have already been extracted as a result of a previous site reclamation scheme or other development; or

b) extraction of minerals is not feasible, for example due to significant overburden or because mineral extraction would lead to or exacerbate ground instability; or

c) prior extraction of minerals would result in abnormal costs and / or delays which would jeopardise the viability of the development; or

d) there is an overriding need for the development which outweighs the need to safeguard the mineral resources present; or

e) extraction of minerals would have unacceptable impacts on neighbouring uses, the amenity of local communities or other important environmental assets.

12.33 Where prior extraction is proposed, conditions will be imposed on any grant of permission requiring applicants to provide details of the types and tonnages of minerals extracted once the scheme has been completed.

Existing Minerals Sites

12.34 Minerals can only be worked where they are found and in seeking to plan for a steady and adequate supply, the Plan must make provision to not only safeguard minerals resources, but also to deliver mineral sites and associated mineral infrastructure sites. As such, existing mineral sites and mineral infrastructure sites need to be safeguarded for continued use and to retain the potential of the areas in which they occur. This is particularly important with the demand for housing and employment land, which is set to increase over the plan period with the planned housing and economic growth in the Black Country.

12.35 The 2020 Black Country Minerals Study identifies 'buffer zones' around existing mineral extraction and mineral infrastructure sites. Given the proximity of permitted mineral sites to existing development in the Black Country, it is considered that the application of the Mineral Products Association's recommended 250m buffer zone around every existing mineral site is unrealistic. A 150m buffer has been applied instead. Any non-mineral development within this 150m buffer zone will need to demonstrate it will not have any unacceptable impacts on these sites that would prevent them from continuing to operate.

Evidence

- Black Country Joint Core Strategy: Minerals Study 2008, RPS

- Walsall SAD & AAP Minerals Study (2015), Amec Foster Wheeler

- Walsall Site Allocation Document: (2019), Walsall Council

- Black Country Minerals Study: Review of the Evidence Base for Minerals to support the preparation of the Black Country Plan (2020), Wood

Delivery

- Development Management – evaluation of applications for non-mineral development within the MSAs and within the 'buffer zones' around mineral extraction sites, preferred areas and mineral infrastructure.

- Developers – will be expected to consider the impact of proposed development on mineral resources and mineral operations in accordance with the policy.

Issues and Options consultation response

12.36 Policy MIN2 will replace the relevant sections of existing BCCS Policy MIN1. The Issues and Options Report (2107) recognised the need to safeguard minerals resources in the Black Country but that this needs to be balanced against the need to bring forward housing and employment growth.

12.37 Having regard to the representations received to the Issues & Options consultation and the recommendations of the Black Country Minerals Study the following preferred policy options for minerals in the Black Country were identified:

- Adopt more tightly defined MSAs for both sand and gravel and brick clay focused on the mineral resource in Walsall;

- Make policy provision to enable prior extraction of minerals within the MSAs, where feasible and economically viable, to prevent the sterilisation of mineral resources by non-mineral development; and

- Safeguard existing mineral and mineral infrastructure sites and include an appropriate 'buffer zone', in accordance with good practices to ensure a consistency of approach.

Preferred Areas for New Mineral Development

12.38 This policy identifies the preferred areas for mineral extraction and other types of mineral development in the Black Country during the plan period, having regard to the requirements identified in Policy MIN1, the availability of mineral resources and the constraints to mineral working and processing in the plan area.

(8) Policy MIN3 - Preferred Areas for New Mineral Development

- The preferred areas for new mineral development over the plan period are identified below and are shown on the Minerals Key Diagram and the Policies Map. New mineral extraction proposals will be supported in these locations, provided that the development would comply with Policy MIN4, and would not conflict with other policy requirements or site allocations in this plan or in any other adopted development plan.

Aggregate Minerals

Sand and Gravel

- Sand and gravel production are currently only permitted at the Branton Hill Quarry Extension site in Walsall (MX1). Further sand and gravel extraction will be supported in principle in the following Preferred Area:

- MP1: Birch Lane, Aldridge, Walsall.

- Sand and gravel extraction will also be acceptable elsewhere within the MSA for sand and gravel (see Policy MIN2). When considering new sand and gravel extraction proposals, significant weight will be given to the contribution this would make towards the sand and gravel supply requirements identified in Policy MIN1.

Borrow Pits

- Short-term, time-limited excavation of fill material for specific engineering projects (‘borrow pits’) will be supported in principle. Such proposals should be supported by evidence that they are as near as possible to the project they will be supplying, and that secondary or recycled materials are either not available or are insufficient to meet the identified need for fill.

Industrial Minerals

Brick Clay

- The extraction of brick clay (Etruria Marl) is currently permitted at the following sites in Walsall:

- MX2: Atlas Quarry

- MX3: Sandown Quarry

- MX4: Highfields North

- Atlas and Sandown Quarries are active clay pits which are supplying the adjacent brickworks, whereas Highfields North is a ‘dormant’ site.

- Due to the constraints on the Etruria Formation resource areas in the Black Country, there is unlikely to be scope for further clay extraction outside of the permitted sites. However, if such proposals should come forward within the Brick Clay MSA during the plan period, significant weight will be given to the contribution that they would make towards providing or maintaining a 25-year supply of clay to a brick manufacturing plant.

Fireclay

- There is a stockpile of fireclay remaining from the former Birch Coppice site in Walsall (MS1). This is the main source of supply to the adjacent Swan Works, which manufactures pot clay blends. The same mineral permission for clay and coal working also applies to another site nearby, Land at Brownhills Common (MX5). Due to the constraints of the Brownhills Common site, mineral working is not expected to take place during the plan period.

- Proposals for clay and coal extraction elsewhere within the Fireclay MSA identified on the Key Diagram, and for the stocking of fireclay following extraction, will be supported in principle where it can be demonstrated that this is essential to maintain supplies of fireclay to brickworks over the long-term, and that there are no alternative sources of supply available. Significant weight will also be given to proposals that would allow for the revocation of the existing ‘dormant’ permission at Brownhills Common.

- Proposals for fireclay and coal working in the vicinity of the Cannock Extension Canal must be accompanied by a Habitats Regulations Assessment (HRA) demonstrating that they would not harm the integrity of the SAC.

Building Stone

- Building stone has not been worked in the Black Country for many years and is unlikely to be substantially worked again during the plan period. However, short-term, time-limited extraction of Dudley (Wenlock) Limestone, Barr Limestone, Gornal Stone, Halesowen Sandstone and Sherwood Sandstone for the repair and conservation of heritage assets constructed of these materials will be supported in principle.

Energy Minerals

Coal

- There is a general presumption against deep mining of coal, surface coal working (except where this is in relation to the working of fireclay) and colliery spoil disposal in the Black Country, unless the proposal would meet the tests of environmental acceptability set out in national policy guidance. Any such proposals will be expected to be fully justified in terms of the economic and energy benefits they will generate. Proposals for the working of coal will also be expected to extract maximum value from other mineral resources associated with coal deposits.

Justification

12.39 Planning policies for minerals should provide for the extraction of minerals of "local and national importance (NPPF paragraph 204), including sand and gravel, brick clay, fireclay and coal, which occur naturally in the Black Country.

Preferred Areas for Sand and Gravel Extraction

12.40 The Branton Hill Quarry Extension site was granted permission in August 2018 (application reference BC64995P). This site is estimated to have just over 1 million tonnes of permitted sand reserves. The extant mineral permission has an end date of 31 December 2027.

12.41 No sites have been submitted for sand and gravel extraction in response to the 'call for sites' between July 2017 and August 2020, and a number of sites have been put forward for housing development within the MSA.

12.42 The Preferred Area at Birch Lane is the same as the Area of Search identified on the Policies Map for Walsall and in the adopted Walsall Site Allocation Document (SAD) 2019. This was itself based on the Area of Search identified in the 2011 Black Country Core Strategy. The identification of this area as a preferred area is justified because there are potentially winnable resources in this area. The preferred area includes a former sand and gravel site in this area which was worked until 2008. As this site remains unrestored, any new sand and gravel extraction proposals in this area will be expected to help facilitate the restoration of this site.

Preferred Areas for Brick Clay Extraction

12.43 The only two active brick clay (Etruria Marl) quarries in the Black Country are Atlas Quarry and Sandown Quarry, both in Walsall. Atlas Quarry supplies Etruria Marl to both the Aldridge and Atlas brickworks. There is also a dormant brick clay site at Highfields North, which is highly constrained by the Jockey Fields SSSI designation and thus considered unlikely to be worked during the plan period. Due to the limitations of the Etruria Formation resource areas in the Black Country, there is unlikely to be scope for further clay extraction outside of the permitted sites.

12.44 No sites have been submitted for brick clay (Etruria Marl) extraction in response to the 'call for sites' between July 2017 and August 2020, and a number of sites have been put forward for housing development within the MSA.

Preferred Areas for Fireclay and Coal Extraction

12.45 There are no sites producing fireclay in the Black Country but extracted fireclay is still being stockpiled at the former Birch Coppice site in Walsall. This is the main source of supply to the adjacent Swan Works, which manufactures pot clay blends. The same mineral permission for fireclay and coal working also applies to the nearby site at Brownhills Common but this site has not been working and as there are no modern working conditions in place, the permission covering this site is dormant.

12.46 Due to the constraints at the Brownhills Common site, mineral working is not expected to take place during the plan period.

12.47 Much, if not all, of the coalfield within the Black County lies in urban areas and therefore the resource is largely sterilised (2020 Minerals Study). Future opencast operations can only occur in association with the redevelopment of large industrial sites.

Alternative Hydrocarbons

12.48 The potential for exploitation of coal bed methane (CBM) will be considered if a petroleum exploration development licence (PEDL) is issued in the Black Country (no PEDLs have been issued within the Black Country to date as set out in the 2020 Black Country Minerals Study). At that stage, appropriate guidance will be incorporated into LDFs either through a review of this plan or through another DPD. Proposals coming forward in advance of this will be assessed against the guidance in Policy MIN4 and the following conditions will apply:

a) Any permission granted for the extraction of CBM will be temporary, and subject to conditions limiting the duration of the operation.

b) Proposals should include details of the area covered by the PEDL, the scale and type of operation, the drilling apparatus to be used (including the height of the rig or wellhead), and the site where the wellhead will be stationed.

c) A separate application may be required to relocate a wellhead.

d) Drilling apparatus should be appropriately screened and sited to minimise noise and potentially harmful visual impacts (see Policies ENV2 and MIN4).

12.49 The 2020 Black Country Minerals Study identifies that Black Country geology is unsuitable for fracking. Furthermore, in November 2019 the UK Government issued a moratorium on all fracking activity in England.

Evidence

- Walsall SAD & AAP Minerals Study (2015), Amec Foster Wheeler

- Walsall Site Allocation Document: (2019), Walsall Council

- Black Country Minerals Study: Review of the Evidence Base for Minerals to support the preparation of the Black Country Plan (2020), Wood

Delivery

- Development Management – evaluation of application for non-mineral development within the MSAs and within the 'buffer zones' around mineral extraction sites, preferred areas and mineral infrastructure.

- Developers – will be expected to consider the impact of proposed development on mineral resources and mineral operations in accordance with the policy.

Issues and Options consultation response

12.50 Policy MIN3 will replace the relevant sections of existing BCCS Policies MIN2, MIN3 and MIN4. The policy sets out those preferred areas for new mineral development and should be read in conjunction with the new Policy MIN4.

12.51 In response to the representations received in response to the Issues & Options consultation, the policy includes a presumption in favour of borrow pits as well as support in principle for the use of identified building stone materials for the repair and conservation of heritage assets constructed from those materials.

Managing the Effects of Mineral Development

12.52 This policy sets out the requirements that planning applications for mineral working and minerals infrastructure will be expected to address. The policy identifies some general requirements that mineral development proposals will need to satisfy, and then lists several additional criteria against which such proposals will be further assessed. The policy applies to both proposals at existing sites and those at new ones.

(5) Policy MIN4 - Managing the Effects of Mineral Development

General Requirements for Minerals Developments

- All mineral proposals at both new and existing sites should demonstrate how they will contribute towards Strategic Objective ‘Meeting our resources and infrastructure needs’, Strategic Priority 14 and the strategic objectives of Policy MIN1.

- Proposals should minimise waste and provision should be made for the extraction, re-use, or recycling of any other potentially useable materials.

- Working plans and restoration proposals should include measures to maintain the stability of the working face, site, and surrounding area.

- When working ceases, all plant and equipment should be removed, and sites should be restored as soon as possible.

- The working, processing or recycling of minerals must accord with all other policies in relation to the protection of the environment, public amenity and health, and surrounding land uses as set out in this plan or in any other adopted development plan – or otherwise demonstrate that other material considerations outweigh any policy conflict.

- Restoration programmes and after-uses for former mineral workings should reflect local character, include provision for after care, and where appropriate contribute towards environmental quality and infrastructure.

- Long-distance transport or haulage of material should be avoided wherever possible, and the potential for transporting material by rail or inland waterways should be explored where feasible.

- Proposals should address the impact of transporting minerals and mineral products on the highway network and should be accompanied by a Transport Assessment if generating a significant number of vehicle movements.

Additional Assessment Criteria for Minerals Developments

- In addition to the general requirements set out above, proposals for mineral working or mineral-related infrastructure at both new and existing sites will be further assessed in terms of:

- minimising any adverse visual impacts;

- effects on natural, built, and historic (including archaeological) environments and on public health;

- generation of noise, dust, vibration, lighting, and excessive vehicle movements;

- compatibility with neighbouring uses – taking into account the nature of the operations, hours of working, the timing and duration of operations and any cumulative effects;

- harm to water quality and resources and flood risk management;

- ground conditions and land stability;

- land use conflict – proposals should demonstrate compatibility with the uses already present within the surrounding area;

- impacts on the highway, transport, and drainage network;

- where necessary, mitigation measures should be identified to reduce any adverse effects to an acceptable level.

- The above criteria will be used to identify and select sites for inclusion in other development plan documents (where appropriate) as well as for assessing planning applications.

Justification

National Guidance

12.53 The National Planning Policy Framework (NPPF paragraph 203) stresses the importance of ensuring a sufficient supply of minerals to provide the infrastructure, buildings, energy and goods that the country needs, and therefore that best use needs to be made of these minerals to secure their long-term conservation.

12.54 To this end, the NPPF (paragraph 204) requires that planning policies should:

a) set out criteria or requirements to ensure that permitted and proposed operations do not have unacceptable adverse impacts on the natural and historic environment or human health; and

b) ensure that worked land is reclaimed at the earliest opportunity, and that high-quality restoration and aftercare of mineral sites takes place.

12.55 The NPPF (paragraph 205) then places a number of requirements on minerals planning authorities when considering proposals for mineral extraction – including as to adverse impacts on the natural and historic environment and on human health, cumulative effects of multiple mineral facilities, control and mitigation of noise, dust and vibration, and restoration and aftercare at the earliest opportunity and to a high environmental standard.

General Requirements for Mineral Developments

12.56 This policy sets out the general requirements that will apply to all proposals involving the development of mineral infrastructure and mineral working.

12.57 Mineral infrastructure proposals are defined as storage, handling, and processing facilities (such as depots and recycling facilities) and transportation facilities (such as rail sidings, rail heads and canal wharves). Mineral working proposals include activities such as prior extraction in advance of a redevelopment scheme, extensions to existing quarries, new quarries, borrow pits, stockpiles, and exploitation of coal bed methane.

12.58 Mineral developments differ and early discussion with the mineral planning authority is recommended to clarify the scope and detail of information that will be required. It will be important that the applicant demonstrates the proposal to be consistent with national policy guidance and the overall Spatial Strategy.

Environmental and Amenity

12.59 Although a temporary activity, quarrying can have negative impacts on the areas affected. Such impacts need to be carefully managed, to maintain the environmental quality and amenity of neighbouring uses. For example, proposals should consider the potential:

a) impacts on air quality arising from the transportation of material or dust and particles from excavation and processing;

b) impacts on important environmental assets such as sites designated for their importance for biodiversity / geodiversity, historic buildings, conservation areas, and important archaeological remains;

c) visual impacts on the local landscape, particularly on prominent and highly visible sites;

d) impacts on local communities (including their health) near to mineral handling or production sites.

Cumulative Impacts

12.60 The cumulative impact on the amenity of local communities already affected by quarrying is also an important issue. One of the main sources of complaint is noise and dust from heavy goods vehicles, so haulage routes should minimise these impacts where possible. Without proper management and mitigation, a concentration of quarries and related activities may make particular areas less attractive to live in.

Transportation

12.61 There is little scope for the transportation of minerals by modes other than road in the Black Country, as the rail network does not reach the main mineral resource areas, and the canal network is generally not considered suitable for transporting minerals other than on a short-term temporary basis. Nevertheless, and in the interests of moving towards more sustainable transport, proposals should consider the potential for moving mineral products by rail or inland waterways where feasible.

Monitoring

12.62 The BCA have a statutory duty to monitor aggregates production and will also need to monitor brick clay production if they are to establish whether their policies are being implemented successfully. Where relevant, applicants should provide information on the extent of reserves and the quantities of material likely to be produced and used per annum. Where regular updates are required for monitoring purposes, conditions may be imposed requiring operators to provide this information.

Evidence

- Black Country Joint Core Strategy: Minerals Study 2008, RPS.

- Responses to the BCP Issues and Options stage consultation (3 July to 8 September 2017).

- Black Country Minerals Study: Review of the Evidence Base for Minerals to support the preparation of the Black Country Plan (2020), Wood.

Delivery

- Development Management – pre-application discussions and subsequent evaluation of applications for mineral working and minerals infrastructure within the Black Country.

- Developers – will be expected to consider and satisfy the general requirements and additional assessment criteria set out in this policy when submitting their minerals development proposals.

Issues and Options consultation response

12.63 No Issues and Options (I&O) consultation stage representations or comments were made regarding the adopted Black Country Core Strategy (BCCS) Policy MIN5 'New Proposals for Mineral Developments'.

12.64 A lack of any objections or concerns made to BCCS Policy MIN5 suggests that this policy as currently exists is considered appropriate and satisfactory – there is therefore no I&O consultation stage requirement that the emerging BCP replacement Policy MIN4 'Managing the Effects of Mineral Development' should be significantly different.

Monitoring

|

Policy |

Indicators |

Targets |

|

MIN1 |

Maintenance of 25% contribution made to the WMMA sand and gravel landbank as reported through the annual Local Aggregate Assessment (LAA). |

n/a |

|

Maintenance of 2017 levels of aggregates produced from secondary and recycled sources, as reported through the annual LAA. |

n/a |

|

|

MIN2 |

Applications for non-mineral development within the MSAs and within the 'buffer zones' (identified in the 2020 Black Country Minerals Study) around mineral extraction sites and mineral infrastructure that comply with the safeguarding policy. |

100% |

|

MIN3 |

Number of applications for minerals extraction within the MSAs and Preferred Areas compared to the number of applications for minerals extraction outside MSAs and Preferred Areas. |

100% of applications within MSAs and Preferred Areas. |

|

MIN4 |

Percentage of applications for mineral related development satisfying the requirements set out in Policy MIN4. |

100% |

[95] The West Midlands Metropolitan Area (WMMA) comprises the seven unitary authorities of Birmingham, Coventry, Dudley, Sandwell, Solihull, Walsall, and Wolverhampton.

[96] This is based on the potential production rate of the Branton Hill Quarry extension site which has permitted reserves of just over 1 million tonnes and is expected to be worked over seven years up to 2027. Provision for sand and gravel requires careful consideration as well as engagement with other MPAs in the West Midlands that produce sand and gravel, particularly given the potential impact of HS2 on Solihull's permitted sand and gravel reserves and future production capacity.

[97] This is an estimate of annual production at fixed processing sites only and does not include an estimate for recycled aggregates produced and used on-site at construction projects.

[98] In the Black Country, whilst each constituent authority is a Minerals Planning Authority, for minerals planning purposes, past trends and future provision is planned at the West Midlands Metropolitan Area (WMMA) level. Consequently, the data in this chapter assesses the extent to which the BCAs can contribute to the wider identified WMMA minerals requirements.

[99] Trends in annual sales and landbank supplies of construction aggregates are monitored by calendar year (1 January – 31 December) rather than by the usual monitoring years (1 April – 31 March), therefore the sand and gravel requirement for the plan period runs from the 2019 calendar year to the 2039 calendar year.

[100] CLG (2011), Collation of the results of the 2009 Aggregate Minerals Survey for England and Wales, Table 11 and CLG (2016), Collation of the results of the 2014 Aggregate Minerals Survey for England and Wales, Table 11. This includes an estimate of the aggregates sales assigned to the West Midlands region only, which are likely to have been consumed in the WMMA on the basis of a pro rata apportionment by population.

[101] CLG (2007), Collation of the results of the 2005 Aggregate Minerals Survey for England and Wales, Table 11. This does not include any apportionment of the sales assigned to the West Midlands only, some of which must have been consumed in Birmingham and the Black Country.

[102] Actual annual production figures for aggregate minerals are not available, therefore annual sales figures, which are available, are used as a 'proxy.'

[103] Solihull Local Plan Review – Draft Local Plan (November 2016), Policy P13: Minerals